Trust EBWA for Electron Beam Welding

LEARN MORE Atomic Strength Fusion

LEARN MORE Atomic Strength Fusion

Precision electron beam welding for aerospace, energy and science industries

Years in Business

0

Years combined experience

0

Electron Beam Welders

0

About EBWA

Experienced and Accredited

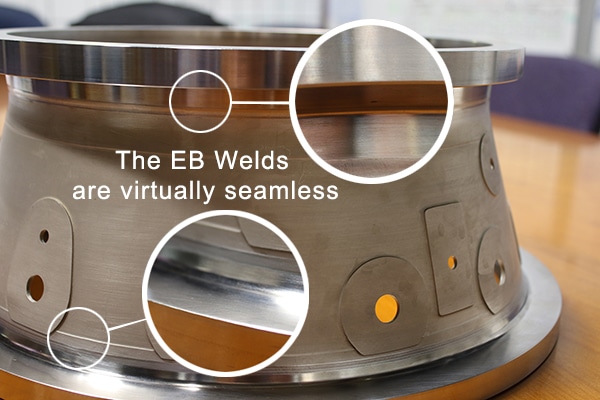

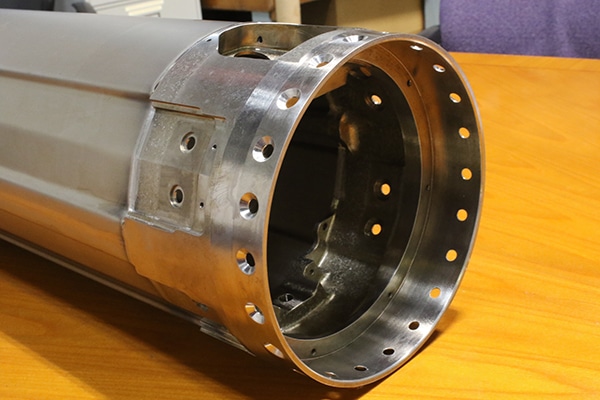

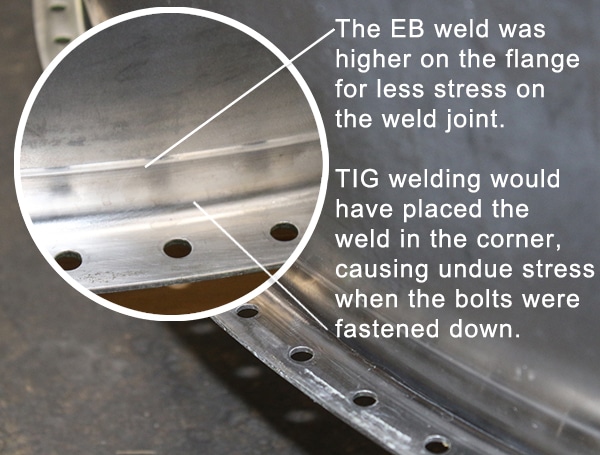

We specialize in Electron Beam Welding

EBWA Industries, Inc. (“EBWA”) is one of the oldest and most experienced electron beam welding shops in the United States. Our electron beam welding services assisted the Apollo Space Program and numerous other NASA projects. We have welded an extremely wide array of military and commercial aviation parts.

Our electron beam welding services are useful in producing parts for all types of engines. We have proficiency in electron beam welding pressure vessels, medical devices, gear sets, test rigs, etc.

Our Customers have presented thousands of different applications and challenges. As a result, we have substantial experience and expertise to help you solve your problems. The reality is that every industry that utilizes welding has been served by EBWA.

EBWA’s workforce makes us who we are and we have been “at it” for a combined 180 years, and that only accounts for the certified welding operators. These years form an expertise un-equaled in the electron beam welding job shop community.

Why EBWA?

The EBWA Advantage

Company Benefits

We protect your information, products, and proprietary data (i.e. we do not compete to machine, reverse engineer your products) Our expertise can compliment your current abilities Competitive pricing and a good value for your highly valued products

Process Benefits

We specialize in complex fabrications to ongoing production pieces for the aerospace industries.

Latest News

News & Articles

Company Benefits

We protect your information, products, and proprietary data (i.e. we do not compete to machine, reverse engineer your products) Our expertise can compliment your current abilities Competitive pricing and a good value for your highly valued products

Process Benefits

We specialize in complex fabrications to ongoing production pieces for the aerospace industries.

“We had a critical hardware need that required a turnaround in a very tight window of time. One of our key vendors on the project was an EB welding service that met our specs, but also could expedite the project. We have a long-standing relationship with C.F. Roark and EBWA. The standard turn time is 2-3 weeks. We needed the parts turned in 2-3 days, and not just for a one-off piece. We needed this extended over 5 weeks and EBWA was able to meet our demands. As a result, we were able to meet our deadlines thanks to Roark/EBWA.”

Senior Supply Chain Manager International Aviation OEM

“EBWA has been a strategic supplier to TRIUMPH for over 30 years. They continue to demonstrate their partnership through performance, and continuous improvements. For us, Quality and On-time delivery is imperative. We cannot have questions or doubts about it. EBWA has demonstrated that they are up to the task, be it large or small jobs. This specifically stood out earlier this year, when we had a stretch delivery targets to meet for one of our large customers. EBWA leadership provided me the commitment and detailed delivery plan. EBWA delivered quality product on time and the engagement on providing us updates was top-notch. This demonstrated performance has enabled Triumph Gear Solutions to secure a contract extension with one of our large customers. In essence, EBWA’s commitment to continuous improvement, on-time delivery and quality have made them a key partner for us and I certainly appreciate it.”

Iqbal Singh, General Manager Triumph Gear Solutions

EBWA is a proud member of the C.F. Roark family of companies.

EBWA Industries, Inc. (“EBWA”) is one of the oldest and most experienced electron beam welding shops in the United States.

Contact EBWA